THE ADVANTAGES

If you have to stop production, take flanges loose, and replace screens, please consider our Big Screen™ below.

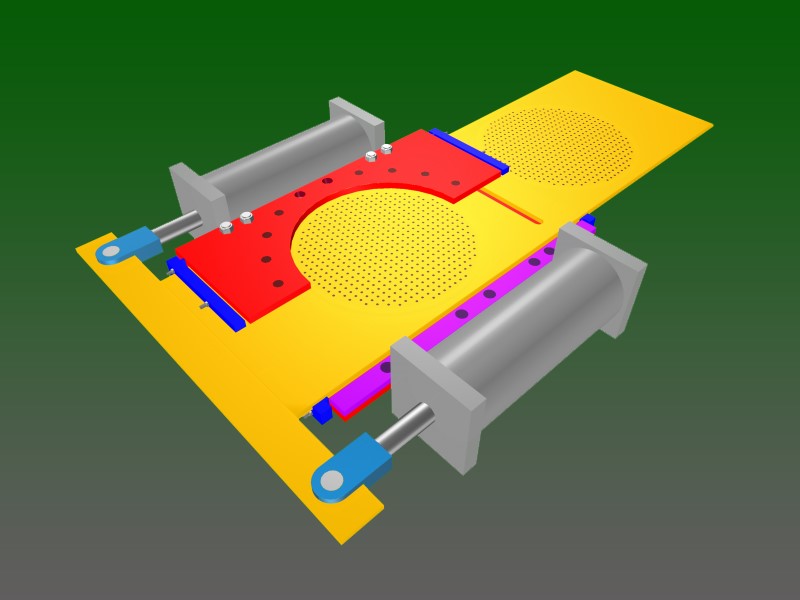

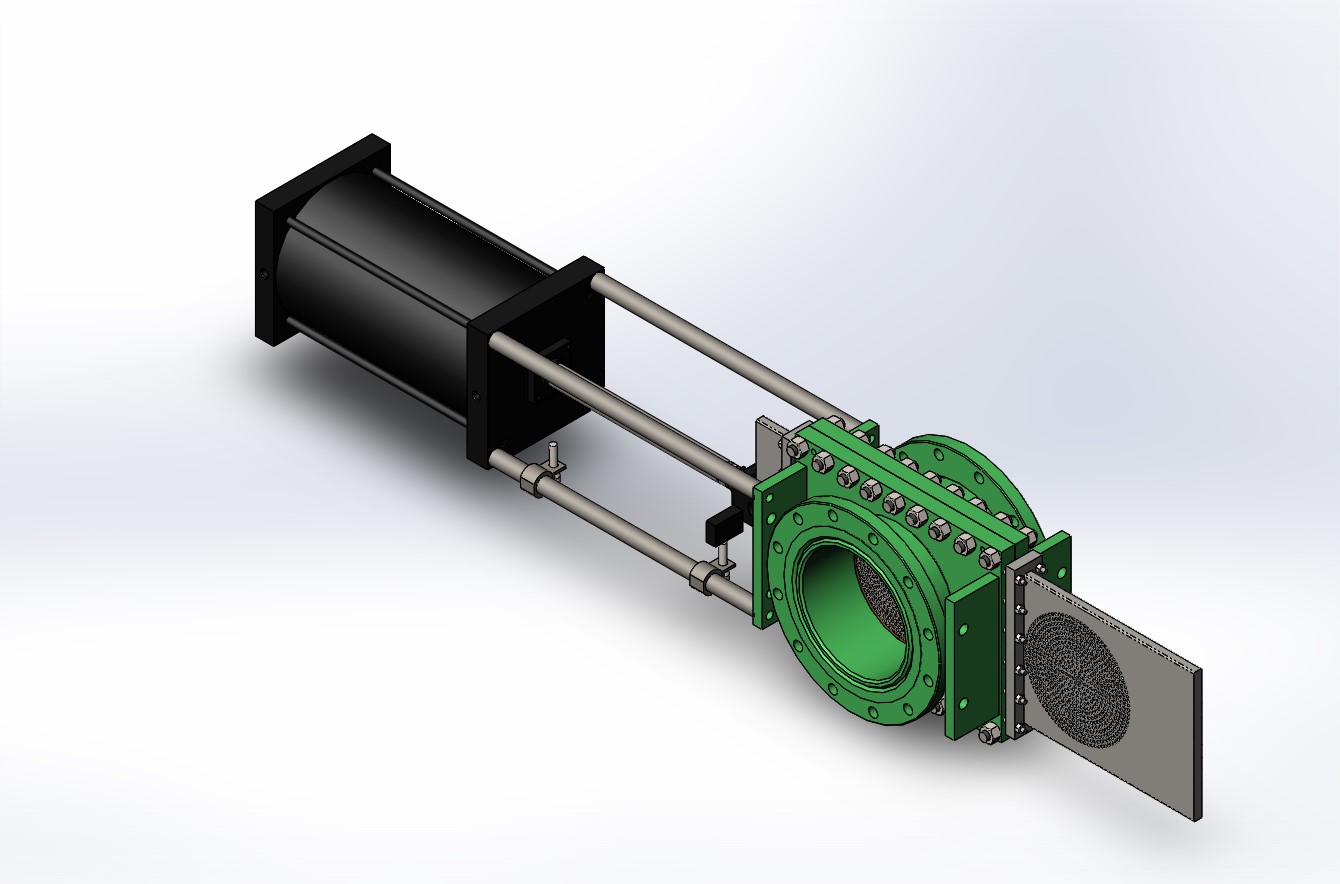

- Big Screen™ replaces screens without stopping production, reducing/eliminating downtime, just by pressing a button.

- The actuator moves the screens, bringing the one that is to be exchanged outside the body and at the same time the clean one into the flow area.

- While the one screen is outside the body it can be cleaned and prepared for the next exchange while production continues.

- Cut rings shear the protruding matter from the screen surface, protecting the seats and ensuring a tight seal.

- Typically supplied with pneumatic operator. Also available with hydraulic, electric, or manual operators.

APPLICATIONS

STANDARD APPLICATIONS INCLUDE:

- Vent on a steaming vessel for turpentine recovery. Rather than replacing screens at every outage, the valve is actuated at an appropriate interval to allow access for the operators to clean the screen. All of this is done with the process running continuously.

- Back up screen behind the rotary screen for the recovery boiler, reducing possible plugging of the heat exchangers and burners.

- Mill water intake. Screen will prevent larger objects (branches, rocks, and debris) from entering the supply line.

- Solids/Gas separation

CUSTOM APPLICATIONS INCLUDE:

- Automated back flush.

- Valve-Screen combination for isolating a line for maintenance.

- Fully adaptable to various screen configurations (2″ to 72″ in diameter) with different hole sizes, different spacing and different face-to-face dimensions. Blade integrated or replaceable screens.

OUR COMMITMENT

We are committed to upholding our most cherished values in every project and task we take on leading to the ultimate goal of establishing and maintaining long term relationships as THE valve solution provider for critical and demanding applications.