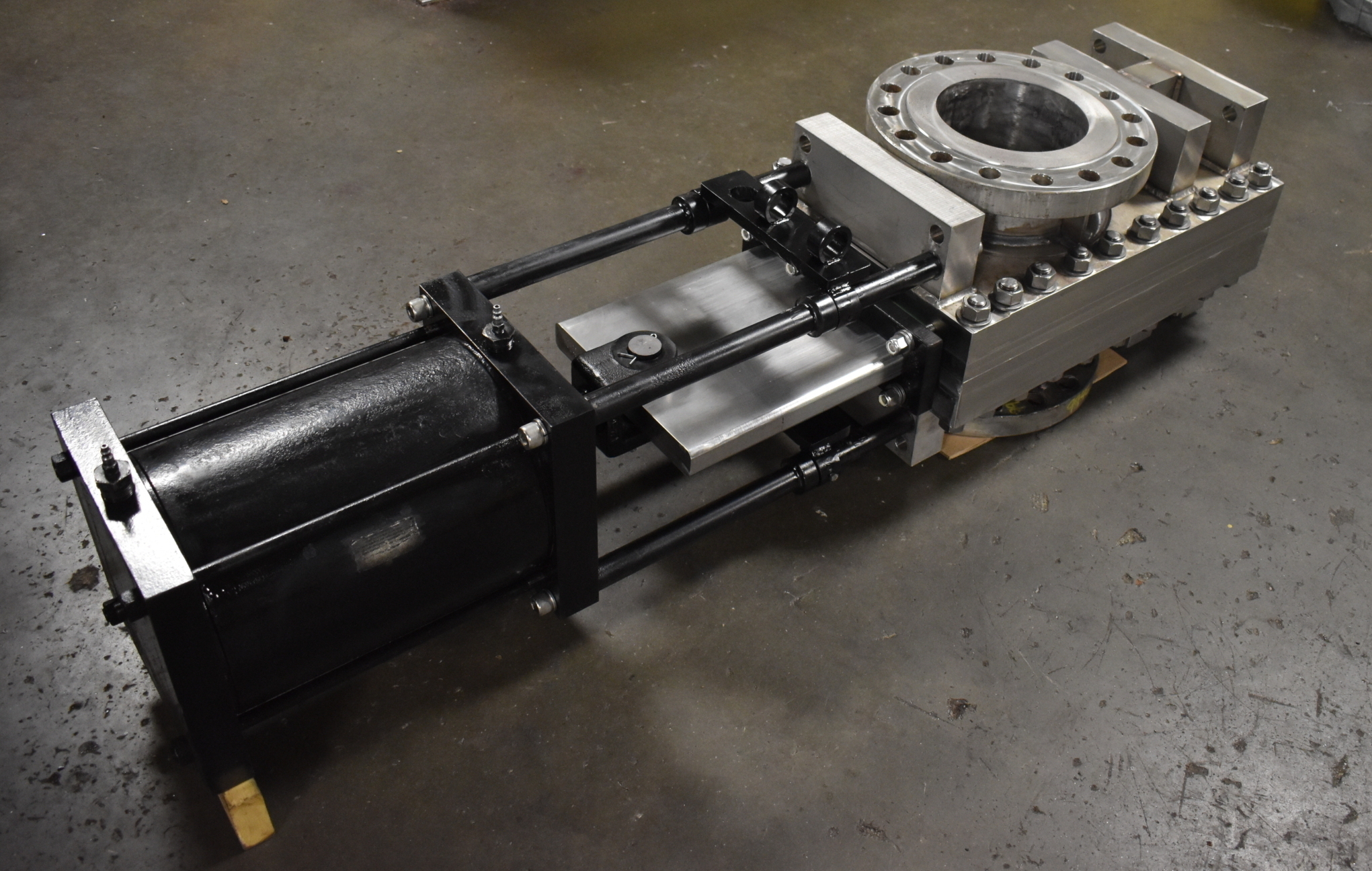

THE BATCH DIGESTER BIG BLOW™ VALVE

Fifty-five Years of Un-Matched Service

The Big Blow™ valve has a long history of providing un-matched reliability and low maintenance requirements in one of the most severe, critical, and demanding services in the pulp and paper industry. The batch digester blow down valve is central to the efficient, safe, and reliable operation of batch digesters, regardless of whether the mill has common headers or individual blow lines.

The Big Blow™ valve has a long history of providing un-matched reliability and low maintenance requirements in one of the most severe, critical, and demanding services in the pulp and paper industry. The batch digester blow down valve is central to the efficient, safe, and reliable operation of batch digesters, regardless of whether the mill has common headers or individual blow lines.

The digester blow valve application is quite violent. Shockwaves of over 10,000psi have been measured as a result of vapor flashing and accelerated material mass impacting valves in common header systems. Digester and blow line movement adds to the stresses that the blow down valve must accommodate. Despite this severe service, the Big Blow™ valve offers superior performance over a long service life. Mean time between refurbishment is typically 4-10 years with some installations on independent blow line systems going over 15 years. This is unmatched by any ball valve or Big Blow™ copycat offering.

DESIGN

The Big Blow™ has several characteristics that make it the ideal valve for this application starting with the robust design and material allotment. It is a robust and heavy-duty valve product designed specifically to the batch digester blow down application. Development over the years has further improved functionality and reliability.

DETAILS LEAD TO UN-RIVALED PERFORMANCE

Integrated and reinforced packing glands:

Developments by SVC and our partners have brought about a material that maintains the seal even under elastic deformation of the valve body. This material is used in addition to Self-Mold to ensure that there is no leakage from the valve despite heavy shock waves and slurry material in the line.

Soft seats:

Reinforced and modified PTFE seats fully retained to maintain position despite shock waves. Preloaded seats maintain a tight shutoff regardless of pressure differential. The Big Blow™ valve can successfully utilize soft seats where ball valves must resort to metal seated designs that are susceptible to damage from direct impacts on the ball and seat surfaces.

Proprietary weld design:

Flange-Nipple-Body welds are designed specifically to handle external forces from digester system on the valve. Indicator gussets provide visual indication of the loads placed on the valve and when the valve should be pulled for evaluation.

Auto-adjusting blade guides:

Specifically suited for handling abrasive, erosive media along with vapor flashing and mechanical shock waves. Proper guiding of blade ensures optimized seal performance and wear life.

Loaded Seats:

Fully loaded seats prevent process material from getting under the seats and causing binds or premature seat wear.

PERFORMANCE GUARANTEE

Perhaps the most unique feature to the Big Blow™ is the unsurpassed Performance Guarantee: 10 years on the valve and 3 years on the wear parts. SVC stands behind our product and have full confidence in the long term performance of the Big Blow™ valve. The Big Blow™ valve will offer the lowest cost of ownership of any valve product in the digester blow down application.

OUR COMMITMENT

We are committed to upholding our most cherished values in every project and task we take on leading to the ultimate goal of establishing and maintaining long term relationships as THE valve solution provider for critical and demanding applications.