BIG KNIFE™

Economical yet High Performance

Big Knife™ valves are a development to bridge the gap between the typical knife-gate valves, which are often treated as throw-away commodity valves with all their many technical disadvantages, and the more expensive and capable Stargate-O-Port-Valve®.

Big Knife™ valves are a development to bridge the gap between the typical knife-gate valves, which are often treated as throw-away commodity valves with all their many technical disadvantages, and the more expensive and capable Stargate-O-Port-Valve®.

When knife-gate valves are used in applications with solids in the flow media, these valves tend to compress the solids into the seat area, over time preventing the valve from closing properly. The SVC Big Knife™ valves are designed for applications with low percentage of solids, liquids, or gasses where better shutoff is required or other challenges such as scale, erosion, or corrosion present more readily.

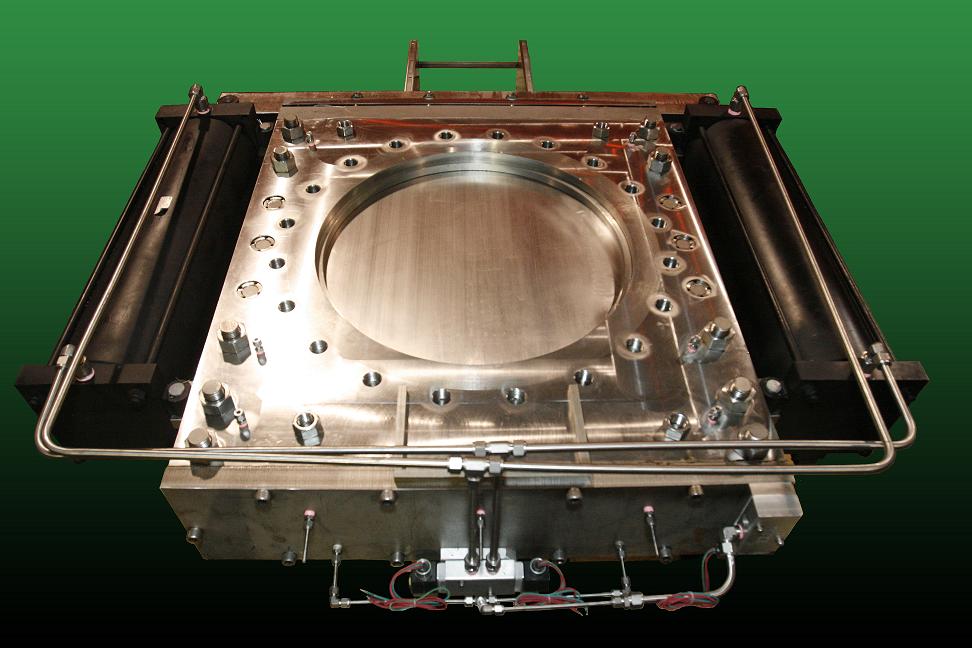

SVC Big Knife™ valve is designed to allow solids to accumulate in the bottom of the valve, to a certain extent, as the valve is being closed. The bottom of the valve can be flushed out in order to prevent compaction of material in that area. The amount of accumulated solids depends on valve size, particle size and percentage of solids in the flow. The other advantage of SVC Big Knife™ design over other knife gate valves is the possibility to clean out the valve bottom if material cannot be flushed out and to do this while the valve is in line. The bottom lid is opened for clean-out.

SVC Big Knife™ valves still retain the bi-directional shut-off feature of our other valve designs. The gate is being guided through live-loaded or preloaded seats through its entire travel.

There are no bent gates at high pressure on reverse flow because of the robust design of the valve.

OUR COMMITMENT

We are committed to upholding our most cherished values in every project and task we take on leading to the ultimate goal of establishing and maintaining long term relationships as THE valve solution provider for critical and demanding applications.