BUILDING PERFECTION

What is a Stainless Valve Company Stargate-O-Port-Valve®? What are the Stargate-O-Port-Valve® advantages over other valves?

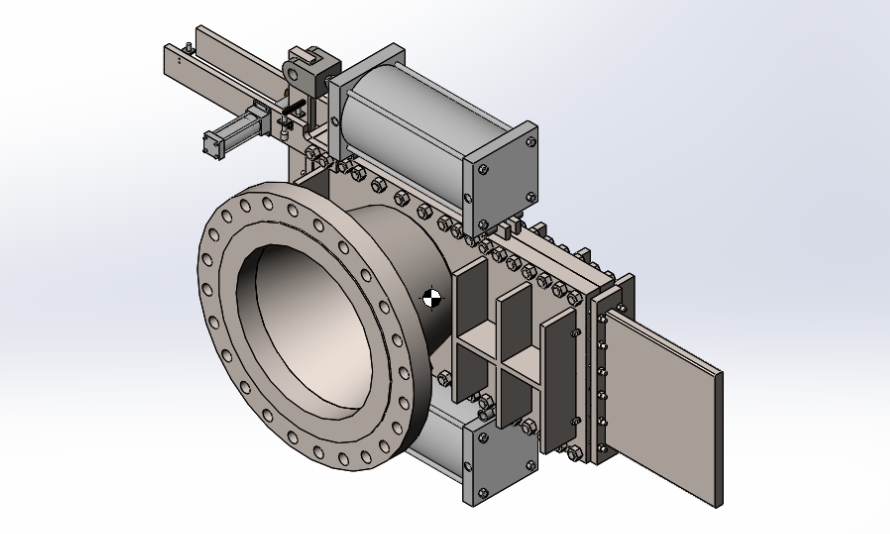

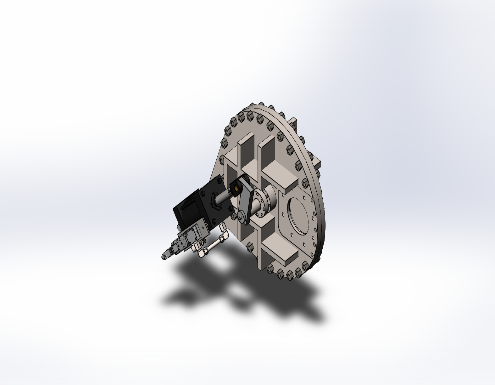

The main characteristic of this type of valve, also called slide-gate valve, through-port valve, or slab gate valve is the well-guided blade passing through both ends of the valve body, having a hole in the middle of the blade. Take a ball valve, flatten it in three dimensions and you have the Stargate-O-Port-Valve, the “FLAT” ball valve. This basic concept has a series of advantages:

The main characteristic of this type of valve, also called slide-gate valve, through-port valve, or slab gate valve is the well-guided blade passing through both ends of the valve body, having a hole in the middle of the blade. Take a ball valve, flatten it in three dimensions and you have the Stargate-O-Port-Valve, the “FLAT” ball valve. This basic concept has a series of advantages:

- The valves are the choice for handling solids in flow media. Liquid, gas and solid flow media or mixtures thereof are easily accommodated.

- Proper actuation of the valve is guaranteed. There is zero change in volume inside the valve body during actuation. This means that solid flow media cannot build up and block actuation or interfere with proper sealing of the valve. There is no other valve type that can make this claim.

- No material gets trapped in the bottom of the valve as is typical with knife gate valves.

- The valve does not require lubrication and, other than occasional packing adjustments, there is virtually no maintenance needed.

- The valve can be used as shut-off valve, flow control valve and, if so specified, a line blind.

- Even in a partially open position the valve has a direct flow path through the valve. Ball valves will have the flow redirected twice and normally directly on the seat surface, exacerbating wear.

- Short face to face dimension, a fraction of the space requirement of a ball valve in the flow direction. Overall construction height is a fraction of what is required for ball valves.

- Foreign matter does not get jammed between the gate and the body. This prevents seat damage so that the valve always seats and seals well.

SUPERB DESIGN

Characteristics of the Stainless Valve Company Stargate-O-Port-Valve® design:

- No metal-to-metal contact. Blade moves in guides at both ends of the valve body. The guiding and sealing of the blade are separate functions allowing the Stargate-O-Port-Valve to be specified for service up to 2500#.

- The seats in the valve are protected and away from the flow area and direct impingement by the flow media. Seats are pre-loaded, live-loaded, or mechanically loaded for tightest shut-off possible, independent of the pressure differential from moderate vacuum to full rated pressure. For service temperatures up to 450F, the valve has a class VI shut-off and most high temperature valves can have a Class V shutoff. The shut off does not depend on a pressure differential between the upstream and downstream side as you would expect with most severe service ball valves.

- Foreign matter cannot get forced between the blade and seat. This prevents seat damage so that the valve always seats and seals well.

- Live-loaded pushers (followers) ensure consistent compression of packing for long leak free operation.

- Locking mechanism locks blade in open and/or closed position for greater maintenance activities or operational process protection. Locking mechanism suitable for LOTO.

- Wetted parts Material of Construction (MOC) is 300 series stainless steel, Duplex, Hastelloy, titanium, Inconel, and other materials available in plate form, even carbon steel, plastics, and aluminum.

- Rugged, heavy-duty construction to handle the most severe service environments. Manufactured to tight tolerances for trouble free service.

- Numerous actuation options; Pneumatic, Hydraulic, Electric, Manual or a combination thereof.

- Actuation speeds up to 10″/s

- The Stargate-O-Port-Valve may be installed in any position in the pipe; vertical horizontal or off-axis, it does not impact the performance of the valve. There is no preferential flow direction.

- Over 97% of the body thickness is solid material, resulting in a very stiff valve body. 3% or less are the gaps between the blade and the side plates.

- Different configurations of the valve layout for applications with space constraints are available. Variations of the basic principle led to the development of diverter valves, screen valves, and the Stargate-O-Port-Valve 360.

OUR COMMITMENT

We are committed to upholding our most cherished values in every project and task we take on leading to the ultimate goal of establishing and maintaining long term relationships as THE valve solution provider for critical and demanding applications.