Gold Valves

The Solution to the Scaling Problem

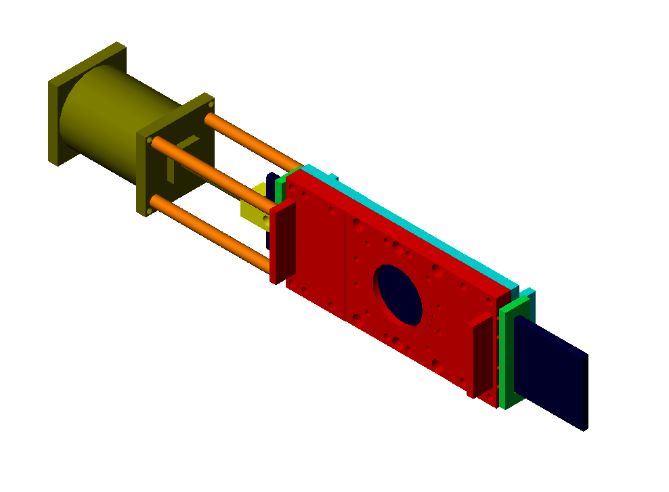

Since 2000 Stainless Valve Co. has done some work with several customers on the application of our Stargate-O-Port-Valve® in applications, where scale formation creates functional problems for the valves, mainly actuation lockup or damage to seats and packing seals. The Stargate-O-Port-Valve® AS has been installed in a variety of industrial applications in pulp, food, petrochemical, and mining. In mining applications, the Stargate-O-Port-Valve® AS has had the most extreme impacts in form of significantly improving performance life. Typically a payoff period of 3-6 months can be expected in the most severe scale forming applications despite a higher capital cost.

S/N ONE Application: Valves For Scale-Forming Service at a Gold Mine

In the first week of 2000 SVC visited a gold mine and found that in a slurry application valves were used that had to be taken out of service every 2-6 weeks. After that short time of service the valves would no longer actuate on hand of severe scale formation on all internal surfaces of the valves. Outage time and labor associated with valve removal and cleanup generated significant operational and maintenance costs.

SVC suggested using the newly developed Stargate-O-Port-Valve® AS for this application. In April 2000 the first valve, 12” 150#, was installed and provided 6 years of continuous service without having to remove the valve to clean off scale. After 4 years of continuous service, the mine purchased an additional 5 valves. To date, only one of the 6 valves had to be refurbished…the first one following 6 years of service.

In 1996, because of an injury, one of our customers had contacted us to find out whether we have a solution for this problem. We devised the concept for the lime storage bin isolation valve. Since installation in 1997, the valve has been in continuous service and has made the operation of the lime storage bin more safe and reliable.