Black Liquor Heater Isolation Valves

“The Solution to the Sticking Scale conundrum”

Dating back to 1995, Stainless Valve Co. has developed a version of the successful Stargate-O-Port-Valve® AS specifically for black liquor heater isolation for continuous digester and batch digester systems. Depending on the process conditions, species of wood used, and the digester kappa, a different severity of scale formation is observed. Customers have reported to us that the stems of ball valves have been broken/twisted and seats have been ripped out, forcing the liquor heater valves to be replaced on unplanned outages. Knife gate valves are not suitable for this application since the liquor will tend to build up in the bottom of the valve and prevent the valve from closing even the first time it is actuated to the closed position.

Key features of the Stargate-O-Port-Valve® AS (SGAS)

Soft Seated for Tight Shutoff: Soft seated ball valves fail very quickly in liquor heater service (scale forming). Metal seated ball valves cannot provide reliable shutoff as the seat or ball can easily be damaged by scale deposits. The SGAS design allows for reliable use of soft seats for a Class VI shut off regardless of scale deposits.

Soft Seated for Tight Shutoff: Soft seated ball valves fail very quickly in liquor heater service (scale forming). Metal seated ball valves cannot provide reliable shutoff as the seat or ball can easily be damaged by scale deposits. The SGAS design allows for reliable use of soft seats for a Class VI shut off regardless of scale deposits.- Short Takeout Dimension: The SGAS valve has a fraction of the takeout dimension of ball valves. The SGAS can also be designed to the same takeout dimensions for drop in replacement.

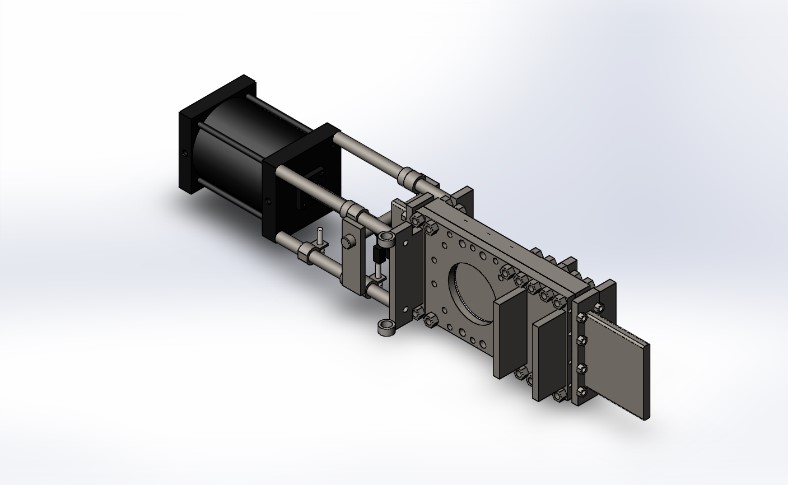

- Visual Confirmation of Valve Position: The blade of the SGAS valve extends out of both packing glands of the valve. The operator can visually confirm the valve position. With a ball valve, especially in scaling service, the stem can be twisted and the operator cannot rely on the valve position indication.

- Lower Air Requirement: The SGAS valve has a significantly lower air use requirement. Metal seated ball valves require large pneumatic actuators to overcome the loading of the metal seat and the “scraping” of the scale. Since the SGAS valve is soft seated, a much lower force is required to actuate the valve.

- Low Refurbishment Cost and Long Mean Time between Refurbishment: The performance history on the SGAS liquor heater valve averages 10 years between refurbishments. When refurbishment is required, cost is typically between 10-15% of new valve cost. The combination provides a low overall cost of ownership.

- High Performance Coatings and Application Specific Seat Design: Based on the operating conditions and site specific observations, the SGAS is custom designed using a variety of seat geometries and proprietary coatings. Scale does not have a chance to damage the valve soft seal components.

- Reduced Bore or Full Bore Designs: The SGAS may be provided with inlet and outlet reducers for reduced bore requirements. Standard configuration is for full bore/full port.

- Tight Tolerances for Superior Performance: There is no change in volume inside the SGAS valve as it actuates so material cannot accumulate inside the valve body. When in the full open position, there are no gaps through the valve; it becomes part of the pipe.

Valve Specifications

- 2”-36” (DN50 – DN900) (Larger sizes on request)

- ANSI 150# - 1500# (PN6 – PN100)

- Proprietary High Performance Coatings

- Application Specific Seat and Seal designs

- Actuation: Pneumatic, Electric, Hydraulic, Manual Gear

- 316L or Duplex Stainless Steel (Available in other materials on request)